Detailed Product Description

Technical Specifications

Be able to inspect multi-rope at same time

Quantitatively detect all types of internal and external flaws

Correctly evaluate residual bearing capacity and service life

I. Overview of URNDT Elevator Wire Rope Testers

Wire rope is a very important, but high-risk component of elevator equipment as it directly concerns the safety of passenger life and property. For a long time, due to the lack of reliable inspection equipment, wire rope safety has always been a “blind spot” of elevator safety management and even the “hidden danger” for passengers’ life.

URNDT elevator wire rope tester adopts the world’s leading and proven weak magnetism inspection technology. It is able to inspect multiple ropes at the same time, and solve effectively the problems concerning elevator rope inspection. This equipment could detect quantitatively all types of flaws such as broken wires, corrosion, abrasion and fatigue of multiple ropes simultaneously. The testing data is presented in a detailed and easy to understand numerical report, with clear conclusions regarding the safety status of the inspected wire ropes.

URNDT Elevator Wire Rope Tester has achieved the perfect combination of innovative technology, practicability and miniaturization. With a PC, testing data is displayed in real time and the testing result is not affected by the speed and load of the target elevator. It is easy to operate and has been recognized by users as the most advanced NDT equipment for elevator wire rope inspection in the world.

II. Inspection Process

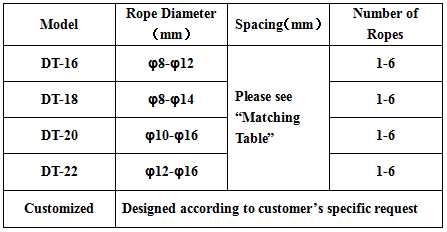

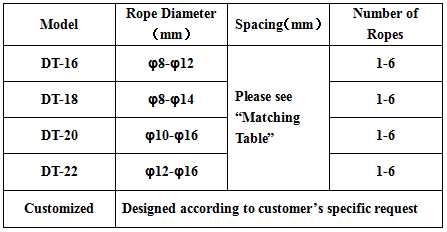

III. Models and Matching Table

III. Models and Matching Table

1. URNDT Elevator Wire Rope Tester Models

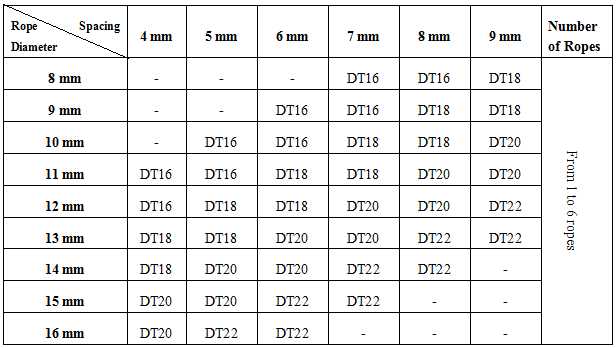

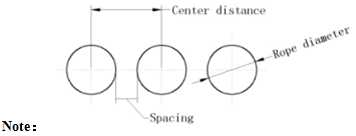

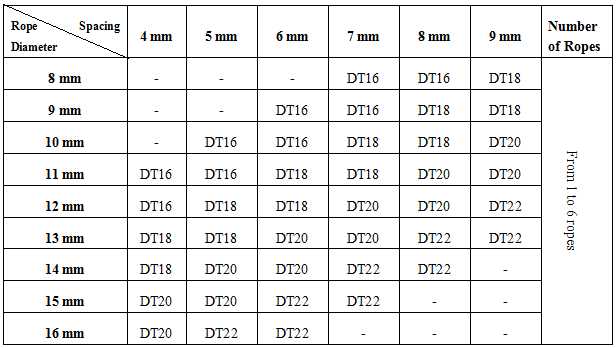

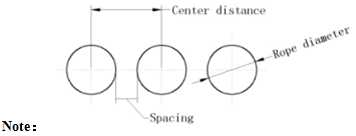

2. URNDT Elevator Wire Rope Tester and Elevator “Matching Table”

IV. Technical Parameters

1. Inspection technology:Weak Magnetism inspection technology;

IV. Technical Parameters

1. Inspection technology:Weak Magnetism inspection technology;

2. Sensitivity:5V/G,Sensitivity modulation value: A = 2.6 V/G;

3. Operating magnetic field strength: < 20 MT;

4. Rope diameter range: 6-36 mm;

5. Number of wire ropes inspected: 1-6 ropes in a single row;Unlimited number of ropes for customized

models;

6. Distance differentiation rate:0.002 m;

7. Rope speed:Vmax = 20 m/s; Controlled rope speed range: V = 0.2-13 m/s; Safety rope speed:V < 2

m/s; inspection accuracy not affected by rope speed;

8. Inspection Accuracy:Pmax < 0.05%;

9. Uncertainty for measuring the loss of effective bearing metallic cross-sectional area (LMA):P < 0.5%;

10. Axial position accuracy: 5Xl0-4 and inspected rope length collating Error:C < l0mm/100 M;

11. Slight defects: detecting capability > 90%

Major defects: detecting capability > 99%

12. Total weight of the testing head unit: ≤ 2.9 kg

13. Dimension (Length, Width, and Height): 252×125×207 mm

14. Working temperature:-30℃~+55℃;No temperature drift phenomenon;

15. Work environment humidity: ≤ 95%RH.

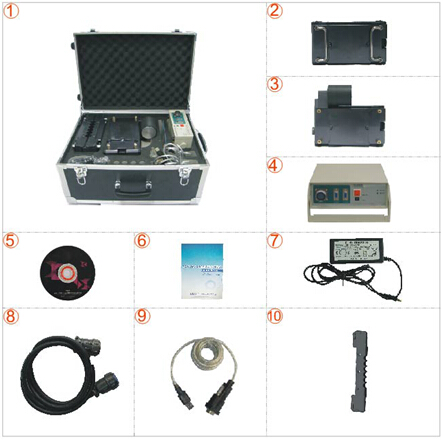

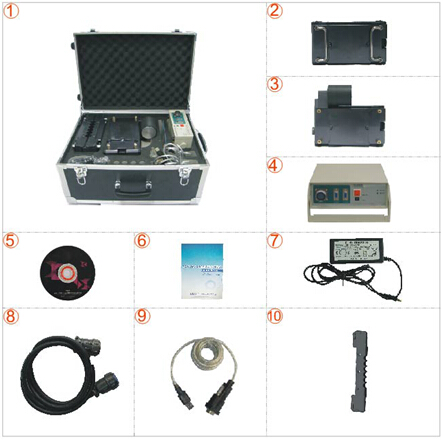

V. Structure and Components

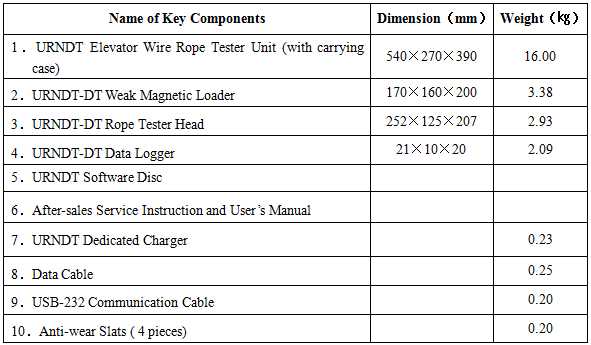

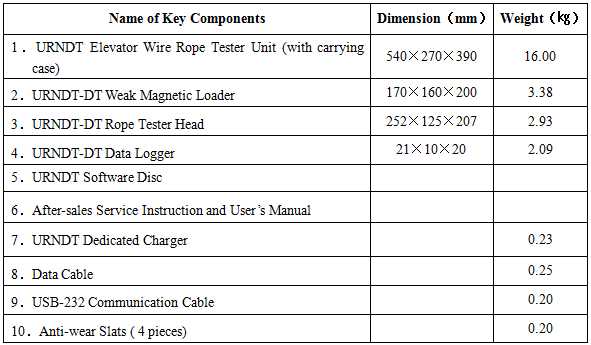

1. Key Components

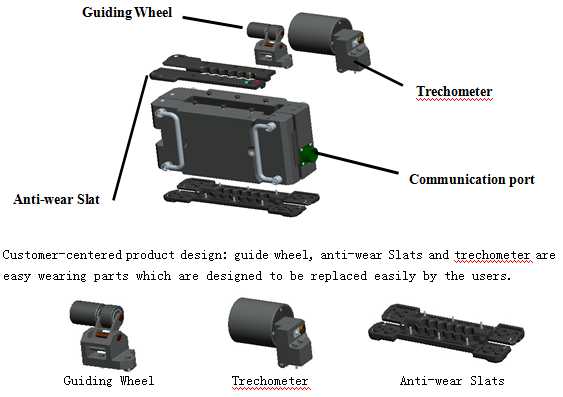

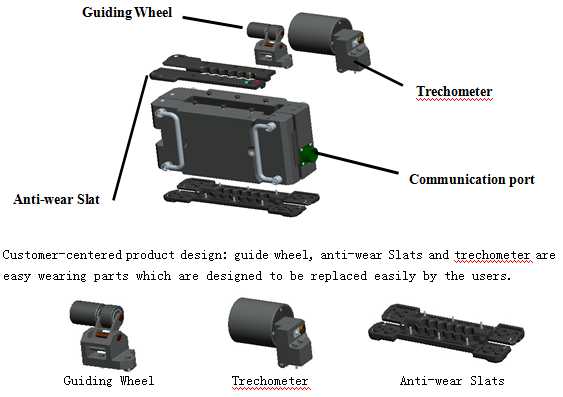

2. Testing Head Mechanical Structure

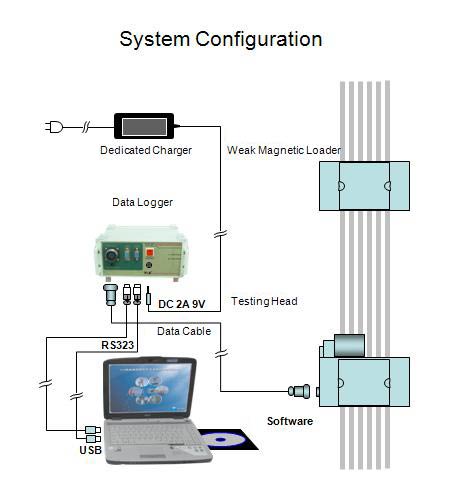

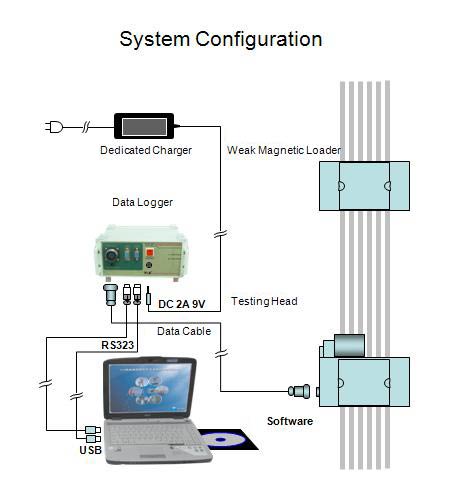

VI. Systemic Functions

1. Quantitatively inspecting broken wires, abrasion, corrosion, fatigue and other flaws and correctly evaluating the

residual bearing capacity and service life of the inspected wire rope;

2. Be able to test multiple elevator wire ropes simultaneously;

3. Quantify broken wires within one lay length and rope diameter reduction;

4. Online inspection and real time Sound/Light alarm at defect point;

5. Online automatic calibration to ensure accuracy of inspection results;

6. Automatic self-diagnosis function to ensure equipment operate reliably;

7. Simple instrument keyboard setting, rolling linear logic interface switch, indicative man-machine conversation,

intelligent embedded program operation and simple and convenient operation;

8. Connected to a portable PC and testing data, flaw curves, data tables and numerical test report could be viewed

right after the inspection;

9. Expert software for data processing, data analysis, test result display, report printing, data storage, and data file

management;

10. High capacity lithium polymer rechargeable battery unit;

11. High strength and anti-corrosion organic insulation materials are chosen for the tester head unit to protect the

operator from electrical shock and other related hazards;

12. CE certified, no magnetic pollution and not interfering the normal operation of other electronic and

communication equipments in the working locale;

13.Splash proof (water and oil), dust and moisture proof.

VII. Product Features

1. High sensitivity and high reliability: the sensitivity of the URNDT Dou Sensor is 70,000-250,000 times higher

than traditional sensors, and the tester’s inspection accuracy, stability, repeatability and reliability are also much

better than similar products;

2. Multiple ropes inspection at the same time and high efficiency: URNDT elevator rope tester can inspect multiple

ropes at the same time. It only needs 10-15 minutes to complete the inspection of all the ropes of an elevator, 15

times more efficient than traditional rope testers;

3. Small size and light weight: the testing head unit weighs less than 2.93KG;

4. Simple operation and easy to use: easy switching the buckle latch to lock or unlock the testing head, friendly

software interface and interactive operation guides;

5. Wide application: URNDT analysis software can not only meet the general users’ need for elevator rope

inspection, but also make it possible for NDT professionals to do in-depth testing data analysis.

6. Online inspection and not affected by rope speed: URNDT elevator rope tester is able to inspect ropes with speed

at 20 m/s and not affected by vibration and shaking;

7. Wide operation temperature range: -35℃ ~+75℃, relative humidity: ≤95% RH and no temperature drift

phenomenon.

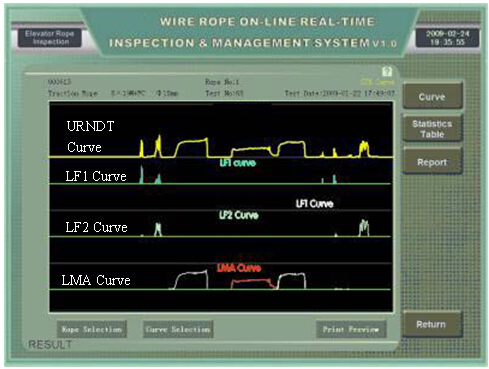

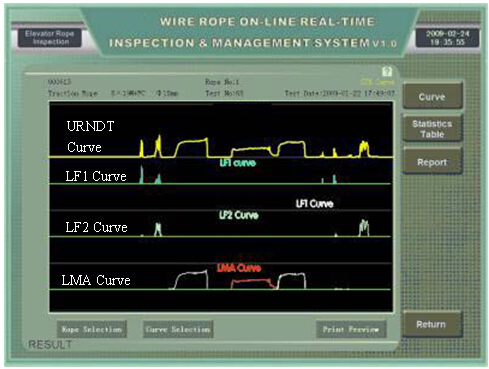

VIII. URNDT Wire Rope Online Real-time Inspection

1. Management System V1.0 and Test Report

URNDT Wire Rope Online Real-time Inspection Management System (V1.0) for Elevators is designed according to the unique needs of the elevator industry. It has the following functions: testing data analysis, testing results multiple formats presentation in flaw curves and data tables, system self-diagnosis and problem warning. It is the ideal safety assistant for elevator users and maintenance companies.

URNDT Wire Rope Online Real-time Inspection Management System (V1.0) has been registered with the State Copyright Bureau (Registry No: 2008SR01487; Certificate No: 088666).

2. Test Report

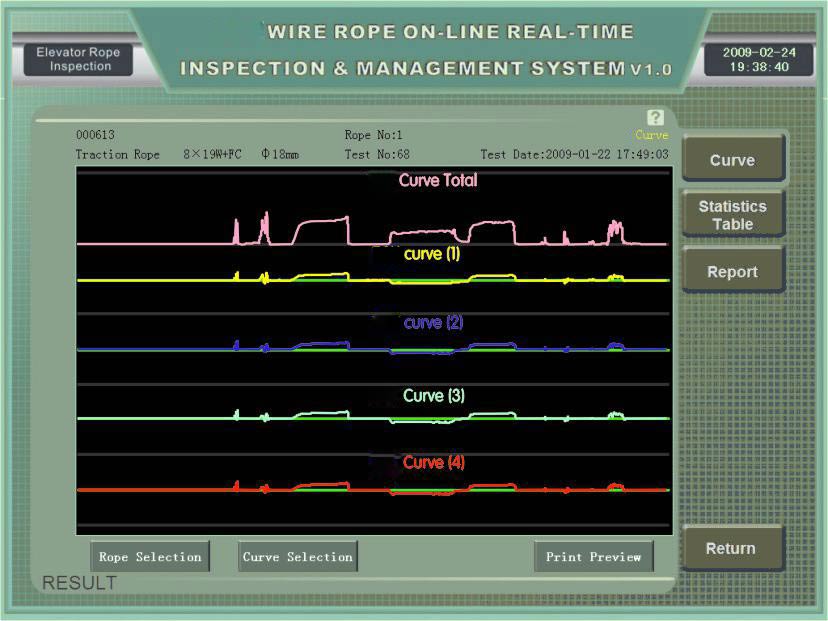

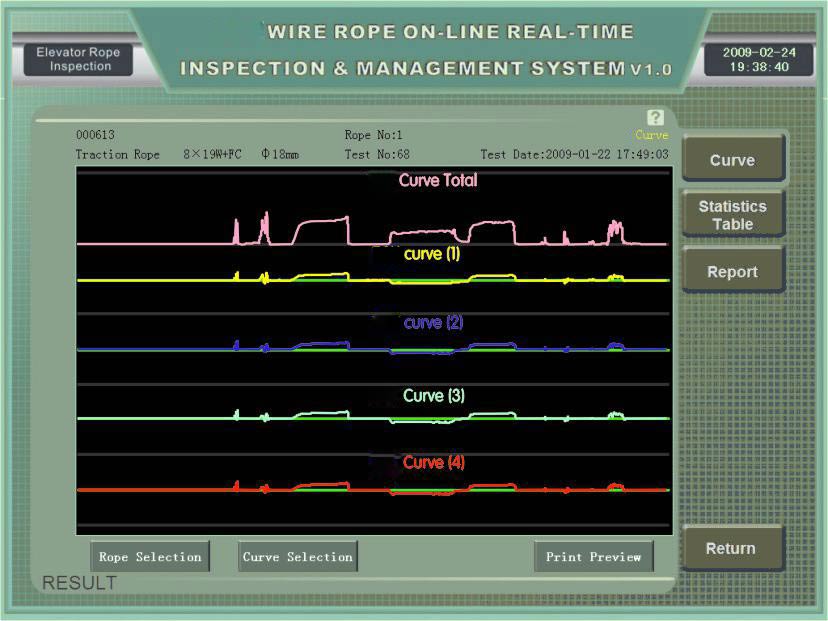

(1)Defect Curve Analysis Interface

Note:

Note:

①. URNDT Curve: a synthesis curve of “LMA & LF”;

②. LF1 Curve: broken wires flaw curve;

③. LF2 Curve: fatigue flaw curve;

④. LMA Curve: abrasion & corrosion flaw curve.

(2)URNDT Curve

(3)Test Report

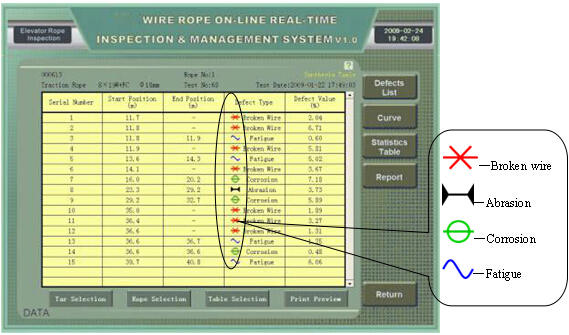

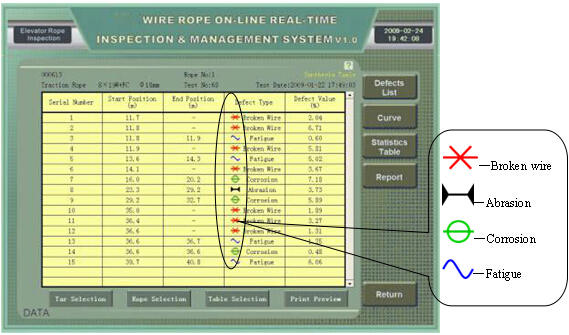

(4) Defects Sequence Table

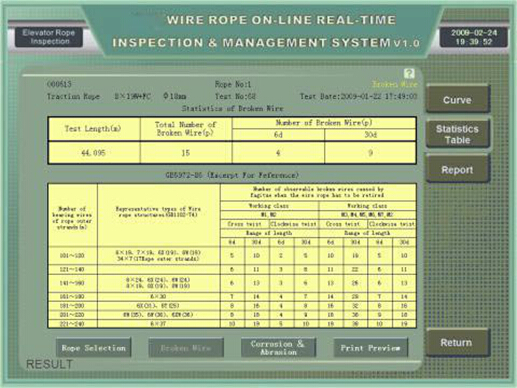

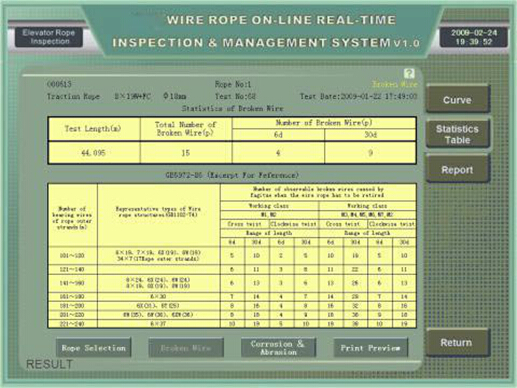

(5) Statistical Table of broken wires (6D/30D)

(5) Statistical Table of broken wires (6D/30D)

(6) Broken Wire Defects Sequence Table

(6) Broken Wire Defects Sequence Table

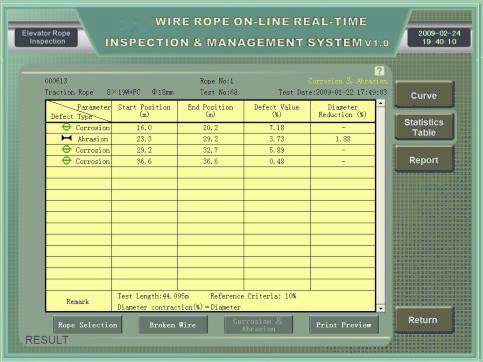

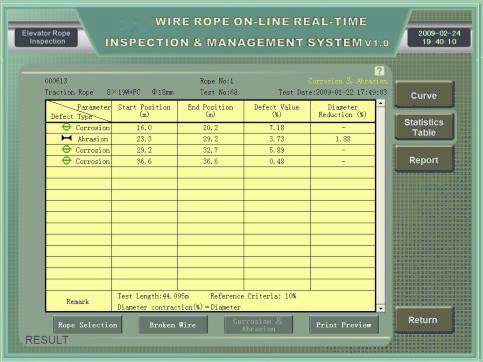

(7) Abrasion & Corrosion Defects Sequence Table

(7) Abrasion & Corrosion Defects Sequence Table

IX. Applications of Elevator Wire Rope Tester

URNDT Elevator Wire Rope Testers have been accepted by elevator manufacturers and elevator maintenance companies and used to inspect wire ropes of both passenger and freight elevators.

Elevator manufacturers like Nippon Otis have entered partnership with URNDT to develop customized rope testers for inspecting their elevators worldwide.

To ensure the safe and reliable operation of elevators in Beijing during the 2008 Olympic Games, Beijing Bureau of Quality and Technical Supervision held a public bidding for 12 elevator rope testers. With its leading and proven technology, and quality customer services, URNDT won the bidding. During the Games, all critical elevators were tested with URNDT rope testers, which made significant contribution to the safety of the Games.